Multiple-nozzle ejectors are more efficient.

The single-nozzle, fixed orifice is the simplest type of ejector. Single-nozzle units are also available with an automatic spindle for special applications.

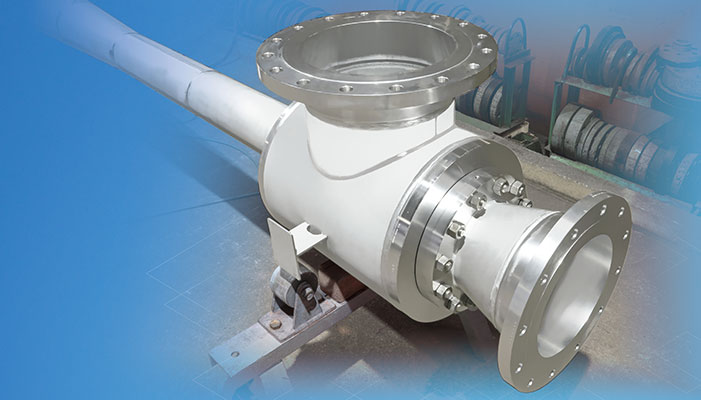

They are applied in processes such as crystallization, deaeration, drying, cooling, high vacuum distillation and deodorization.Įjector systems range from the simple, single-ejector stage to very complex systems with as many as six ejectors in combination with intercondensers.Įjectors are available in either single-nozzle or multiple-nozzle designs. Vacuum Producers: Ejector-based systems are particularly appropriate as primary vacuum producers, particularly where motive steam is almost always available. In the compressors recycle waste steam and low-pressure water vapor discharge, reducing energy consumption by 30% or more. Thermocompressors are ejectors applied to recompressing spent steam and process fluids. The two major functions of ejectors are as follows: Very often, the motive fluid is steam and the device is called a “steam jet ejector.” Basic ejector components are the steam chest, nozzle, suction, throat, diffuser and they discharge (Fig. Instead, it uses a fluid or gas as a motive force. Very simply, an ejector is a pumping device. They are easy to install, operate and maintain.Because they have no moving parts, they are reliable vacuum producers.No source of power is required other than the motive gas.Possible operating problems are discussed. Notes are provided on the mechanical design of steam/gas ejectors including the use of multi-stage units and annular- or multi-nozzles. The equations on which the program is based are fully specified, the input format required is set out in clear tables, and three worked examples illustrate the use of the procedures. For the third case, the ejector dimensions are input together with the loss factors again and a range of entry flow conditions and the program will calculate flow conditions throughout the ejector and at exit. The program will optimise the ejector, calculating the primary nozzle and exit dimensions, and flow conditions throughout. For the second the input is a selection of entry and required exit pressures and flow rates, together with estimates of loss coefficients in the primary and secondary nozzles, mixing duct and diffuser.

If other gases are handled the secondary mass flow rate is converted by the program to an equivalent rate based on the molar mass of the secondary gas. The first is based on experimental data obtained for steam ejectors pumping air at 20 degrees C. Three procedures are provided: a Quick Design Procedure, a Detailed Design Procedure and Performance Prediction. ESDU 94046 introduces a program (ESDUpac A9446) for ejectors in which the primary and secondary flows are non-reacting gases that can be modelled as real.

0 kommentar(er)

0 kommentar(er)